I realize this isn’t what a beginner is likely to build, but I thought you would enjoy this. I can’t imagine how much time it must have taken.

The Brooklyn Bridge

See more here: http://www.toothpickcity.com/index.php

I realize this isn’t what a beginner is likely to build, but I thought you would enjoy this. I can’t imagine how much time it must have taken.

The Brooklyn Bridge

See more here: http://www.toothpickcity.com/index.php

In my recent post about safety equipment for the wood shop I neglected to mention two of the most important items. Although they are not exactly “personal” safety equipment.

I am referring here, to a first aid kit and a proper fire extinguisher.

In case you might not remember, I discussed buying used woodworking tools at garage sales.

In case you might not remember, I discussed buying used woodworking tools at garage sales.

Well, this is one of those things that I would have rather not purchased.

I bought a Delta model 23-710 Sharpening station. The machine is a grinder with two different stones. One was vertical, and the other was horizontal. The horizontal has a mechanism to operate with water. It included a water reservoir and funnel to keep the horizontal stone wet. The reservoir/funnel part was missing. I also did not have any tool holder jigs to keep the tool straight. I even planned how to make my own tool holder. I even made my own spanner wrench to remove the horizontal wheel.

It’s been a while, so I don’t recall what I paid. I think around $20, but I’m no longer sure. If you don’t remember, then it must be a bargain, huh?

I thought this thing must be really cool. And then, after I got it home I began my research. After all, how does this contraption work anyhow? What I learned was that people did not like it at all. The machine shook furiously when I operated it. It seemed that the horizontal wheel was not balanced. On closer inspection, the wheel was not centered on its axis.

Anyhow, after only a bit of research, I determined that customers were routinely not happy with this machine. The largest problem seemed to be that the horizontal wheel was not true.

The vertical wheel seemed to work fine, but that was only half of the machine. Once I had removed the horizontal wheel, I could see that either the wheel was not round, or the spindle was not centered on the spline. I determined the latter.

One option was to purchase a new wheel, but how could I be sure that the new one would be any better than its predecessors.

My choice buy anew wheel, pass it off onto someone that doesn’t know the problem, or pass it on to someone that knows the problem, but has a better solution, or is willing to chance finding a good horizontal grinding stone. I don’t want to deal with the problem.

Motors hardly ever wear out, Any suggestions are welcome.

Happy New Year and Good Morning.

As a follow up to the woodworking safety guidelines posted earlier, I want to discus some personal safety items. These are things I currently have and use as the need arises.

First and foremost I take eye and vision protection very seriously. So many hazards frequent nearly any workshop that eye protection cannot be ignored.

I normally wear prescription lenses, although I don’t need them for close work. My inventory of personal eye safety equipment includes:

Wrap around safety glasses. These are a good idea any time we are in a workshop environment.

Over-the-eye-glass goggles. I have them, but seldom use them. They can also be used by visitors to the workshop. These provide protection if you might need prescription lenses normally. They, by their nature, can also protect against liquid splashes.

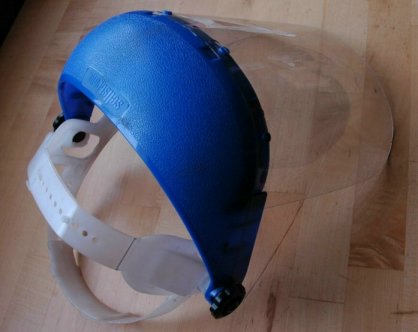

Next, I have full face shield with a flip-up lens. I find this shield beneficial for operations such as grinding when sparks may be flying, or sanding. It may even help to partially control the sawdust in your face.

Hearing protection is next. Some woodworking machinery is extremely noisy and can be damaging to hearing.

I use ear muff type protectors.

I also use gloves, depending on the task. For example, I may want to use leather gloves to protect my hands from splinters. I also use nitrile glove when handling chemicals or something greasy.

For dusty conditions, such as when I am sanding, I use a dust mask. There are many different grades, depending on the particular project.

For chemicals, or painting, I suggest a respirator with the correct cartridge. I don’t have one to display.

I also have a leather welding apron. It’s not specifically for woodworking, but may come in hand from time to time. I still do some welding.

Other items that I consider to be safety related include some tools or accessories to facilitate keeping my hands away from moving cutting blades.

Here, I include push sticks and pads.

Likewise, I also include some examples of feather boards.

This list is not meant to be all inclusive. If you have any suggestion for something I missed, please let me know and I will add it.

Most of these items can be found at most any place that sells tools and are relatively inexpensive. I include hardware stores, home improvement stores, specialty woodworking stores, or ever Harbor Freight as examples. I purchased much of mine at a welding supply store. Some of the better hearing protection can be found at places that sell shooting supplies.

The proper use of these items can keep our woodworking hobby a safe and enjoyable experience.

I previously mentioned that where I was at the Portland Woodworking show I made some purchases.

One of these purchases was a Carter ball bearing guide kit for the bandsaw. The kit comes with two separate guide assemblies and the associated mounting hardware. One assembly was for above the table and the other was to be mounted below the table.

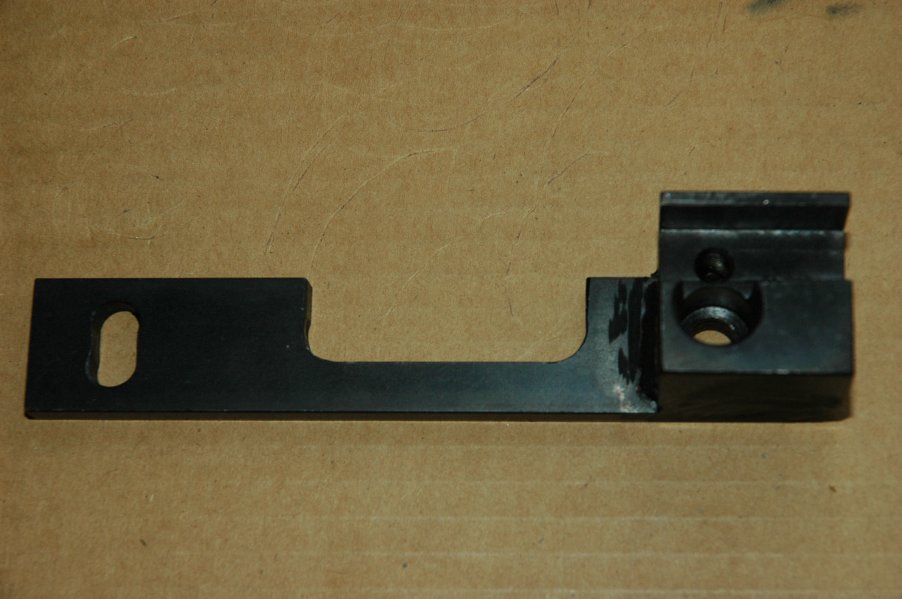

Now it’s time to install my treasure. But, surprise. It didn’t fit. My saw is a Delta 28-276, 14” saw. The lower guide mounting bracket did not fit the mounting holes of my saw. Now, I note that the kit comes with the standard mounting screws and another set of metric screws because Delta has turned to our Chinese neighbors to manufacture their tools.

Further investigation revealed that the hole spacing on the Carter mounting bracket is 4.25” while the hole spacing on my saw is 4.33”. This equates to 110 mm. My assumption was that since the holes were metric, the spacing was also metric and that this was a reasonable round number approximation. The hole spacing on the original mounting bracket precisely matched my saw, 110 mm.

Mounting bracket for band saw guide

So, what to do? I contacted Carter. The first call was answered by a nice lady that just disappeared while I was explaining my problem. I called back and was told that she was on the phone. I was put on hold. The third time’s a charm. I actually spoke to someone who appeared to be knowledgeable about the product. He said that he had never heard of my problem. I asked if 4.25” was the standard spacing in their specifications and he assured me that it was.

I was hoping that I could get Carter to exchange a bracket that fit for mine that didn’t. No such luck Carter had made their product run and weren’t about to make a special order just for me. My options were to modify the part myself or return it to the vendor for a refund. I was reluctant to modify the part because then I could not return it. I was also concerned that if I removed the approximately .080” of metal the screw might fit on only one side. It would have taken a very long time grinding that amount of metal wit a Dremel grinder.

Luckily, I had access to a mill and decided to modify the part myself. I was able to remove somewhat less than the .080” and with a few test fittings, the part fits properly. The guides are now mounted on my saw.

Now, it looks like I need a new blade.

I had it all figured out. I had intended to buy reconditioned. (See previous post.) I had decided on a combination set 18v lithium compact drill/ impact driver made by Milwaukee for $179 with shipping included. Wow!

Then along came Black Friday. Home Depot offered a Makita drill only for $99. So, I abandoned the Milwaukee and ran on down to the nearest Home Depot and braved the BF crowds. Well, they weren’t that big. They were also selling 18v NiCd Makita drills for $29. I watched as someone else quickly grabbed two of them. And I took my prize and went home.

Later, I realized that I had not quite read all of the fine print. My drill had only one battery. A second battery would have cost enough that the bargain would have lost much of its appeal.

I ultimately returned the Makita drill to Home Depot and ordered the Milwaukee set online.

You might think that I would some day learn my lesson. I have experienced Black Friday before and I swore off ever going again, but there I was.

I include this video as a reminder to always reconsider the lesson I ignored.

Have you ever considered buying either used or reconditioned tools? I readily choose reconditioned products over new. Usually they are reduced in price sufficient to represent a significant savings over new. I can only remember one occasion when the product was not as good as new. I have purchased reconditioned tools from a number of outlets and I would willingly do business with any of them again.

There are some misconceptions about buying reconditioned tools. “They’re used and abused.” “They’re worn out.” “They have been discontinued and consequently are obsolete.”

In many cases the product has never been used at all. It could have been an open box product at a store and never was sold. In some cases people actually buy the tools, and return them after finishing their project with it. I mean: what the heck? It’s cheaper than renting.

Many of these tools are lightly used, then returned to the store for a refund. Perhaps the original buyer didn’t like a feature. The tools that are returned to the store may end up in the closeout bargain departments.

Some tools get returned to the manufacturer. The manufacturer can’t sell them as new. They clean it up, if necessary and verify the tool is like new operating condition. Some manufacturers also mark their products indicating that it was reconditioned. It may or may not be in the original packaging. It may also be packaged without the original manuals, and possibly some accessories.

I have noticed mostly hand tools and these include most every kind. They include drills, drivers, circular saws, reciprocating saws, nailers, compressors sanders and more. I rarely have seen the larger floor mounted tools, such as table saws and large shop air compressors. It’s unlikely that a customer would take a larger tool home and then quickly return it.

So, with a little research before spending your tool budget, you can get a lot more tools for the same money compared with new.

I came upon this forum thread about table saw guards. It seems that the majority opinion is that the guard is more trouble than it’s worth, even though the guard definitely enhances the safety.

This is after I included adjusting the guard and splitter when I tuned up my table saw. I must admit that I have not yet given my new setup a good test.

I present this with no argument of my own.

http://www.theamericanwoodworker.com/forum/topics/table-saw-question

I attended the Woodworking Show in Portland Friday. Yeah, I know it’s taken me until today to post on it. This was my first woodworking show. I’m a beginner, you know.

Anyhow, I was very impressed with most everything I saw. They had numerous seminars as well as demonstations from the various vendors. If I keep this up, I too, may develop some woodworking skills. Woodworking tips were flying about everywhere.

Seminars I attended included one on the best use of the bandsaw and on the use and tuning of hand tools, especially planes.

Of course, the man function of a show like this is to sell products and information to the attendees. I did not let them down. I plan to eventually report on my purchases, but that will come later.